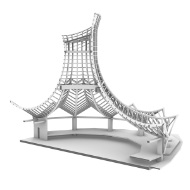

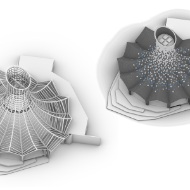

Magician’s hat Knie | The story of the construction project

Facts and figures

Location: Rapperswil (SG)

Finalisation: 2020

Planning period: 2017 – 2018

Construction period: October 2019 – September 2020

Client: Gebr. Knie Schweizer National-Circus AG

Architecture: Carlos Martinez Architekten AG

General planning: Ghisleni Partner AG

Structural planning and statics: Primin Jung Schweiz AG

Timber construction, planning, assembly : Blumer-Lehmann AG

Wood: A total of 224 m3 of spruce/fir from Switzerland and Austria; of which 180 m3 for the supporting framework and 44 m3 for the interior cladding

«We generally like to work with timber. For scheduling reasons, but primarily for environmental reasons.»Carlos Martinez, Architect | Carlos Martinez Architekten

«I come into the magician’s hat every day. I love this building. Everyone who enters the building says wow!»Franco Knie Senior, Co-owner | Gebrüder KNIE, Schweizer National-Circus AG

«The biggest challenge was making the whole structure a reality within eight months.»Stefano Ghisleni, General planning | Ghisleni Partner AG