A complete solution for the waste management company Ulm (DE)

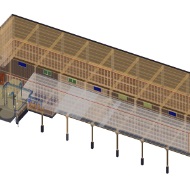

A warehouse for 4,000 tonnes of salt, 150 tonnes of gravel and 12 vehicles, a brine mixing facility with two storage tanks, a salt silo with a capacity of 200 m3 and a fully automated modular conveyor system for loading – these are just a few of the impressive stats for the city of Ulm’s new general waste disposal facility.

Planning challenge

We received the contract for the works as the sub-contractor of a German master builder who entrusted us with the entire planning and implementation process. The construction project was implemented during five month.

«At 55 m long and 20.5 m wide, this is one of the biggest salt and gravel warehouses we have ever produced. All in all, it was a technically demanding project. In addition to the requirements for the silo and brine technology, specific fire safety provisions, a complex static and other additional circumstances, such as the adjoining tram works, had to be taken into account in the planning.»Andreas Grabher, project manager at BL Silobau AG

The dividing walls in the storage space are designed in such a way that they can be moved based on the amount being stored.