Advanced geometry services

We offer our skill and experience as a standalone consultancy service. Offering engineering, design, visualisation and planning for your advanced geometry project.

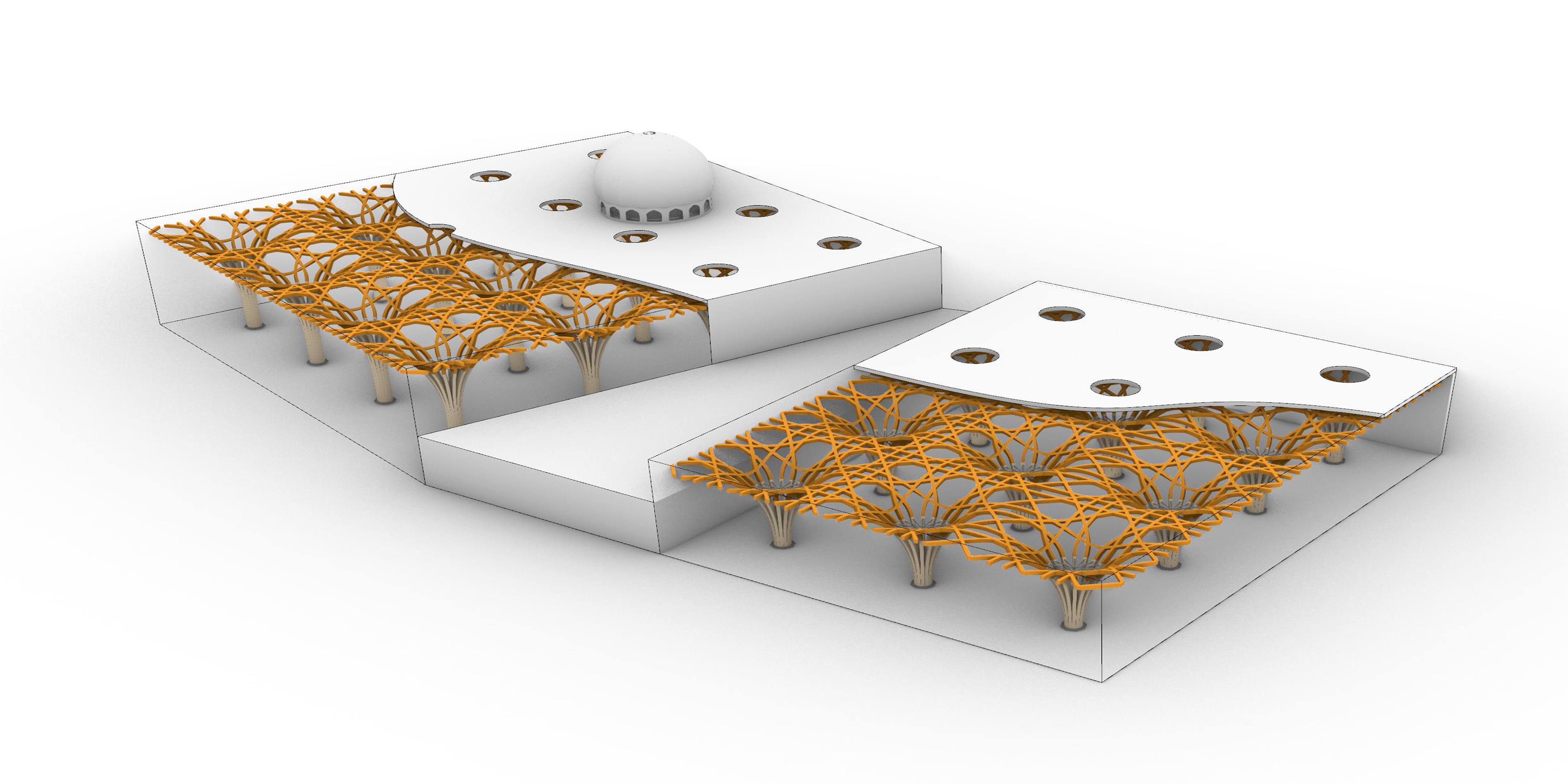

We have completed a number of large, complex and challenging Free Form timber projects, ranging from the Swatch Headquarters in Biel designed by Shigeru Ban, featuring 4,600 parts, to the more recently completed Cambridge Mosque in England, which features a stunning array of vaulted lattice trees and has received a total of 20 architectural and construction awards to date.

With each of these projects, we face new challenges in engineering, design, modelling and manufacture. But we learn something every time, and we take this growing knowledge base with us to the next project.

Our expertise is also not limited to wood. Throughout our history, we have also combined wood with steel and concrete, and have regularly designed and manufactured custom steel components to complement our timber structures.

Therefore, and in keeping with our desire for new challenges, we are pleased to offer our design and expertise for any materials you might be looking to use.

«Simplifying complexity – that’s it!»Ursula Frick, Head of Advanced Geometry

Examples of problems we like to solve and services we can offer you:

- 3D modelling

- Parametric modelling

- Design configurators

- Custom digital tools

- Complete design

- Design & Timber engineering

- Geometry Optimisation

- Machine data / Production drawings

- Consulting partner

- Training

- Fabrication

- Installation

Podcast interview with Ursula Frick and Katharina Lehmann

In the podcast with Bern University of Applied Sciences, Ursula Frick, Head of Geometry and Parametric Design, and Katharina Lehmann, CEO and owner, are interviewed on various topics relating to timber construction. You will find out how we got started in the field of parametric planning and what our commitment to environmental protection entails.